Storage Boxes from scraps – Quick & Dirty

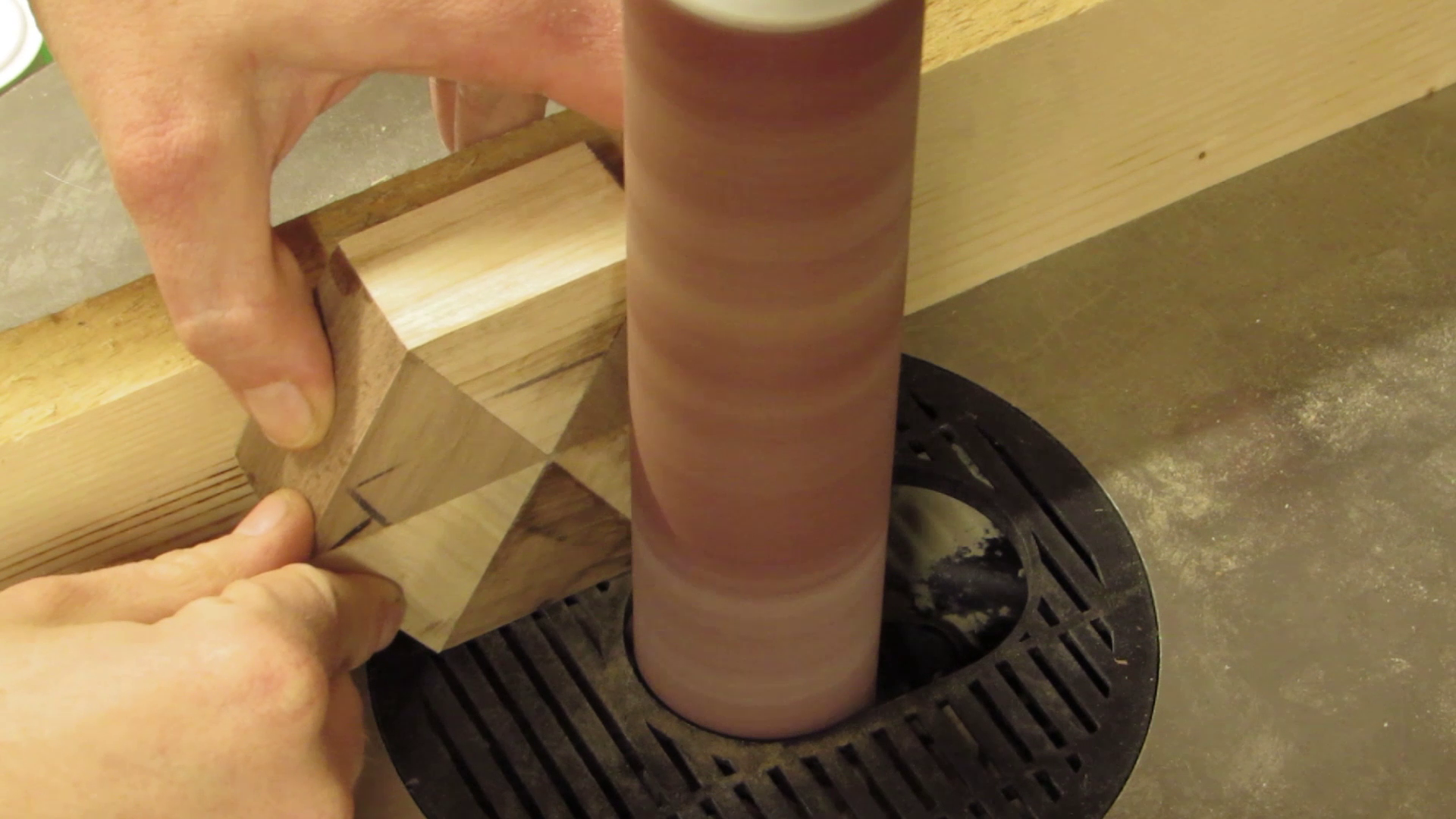

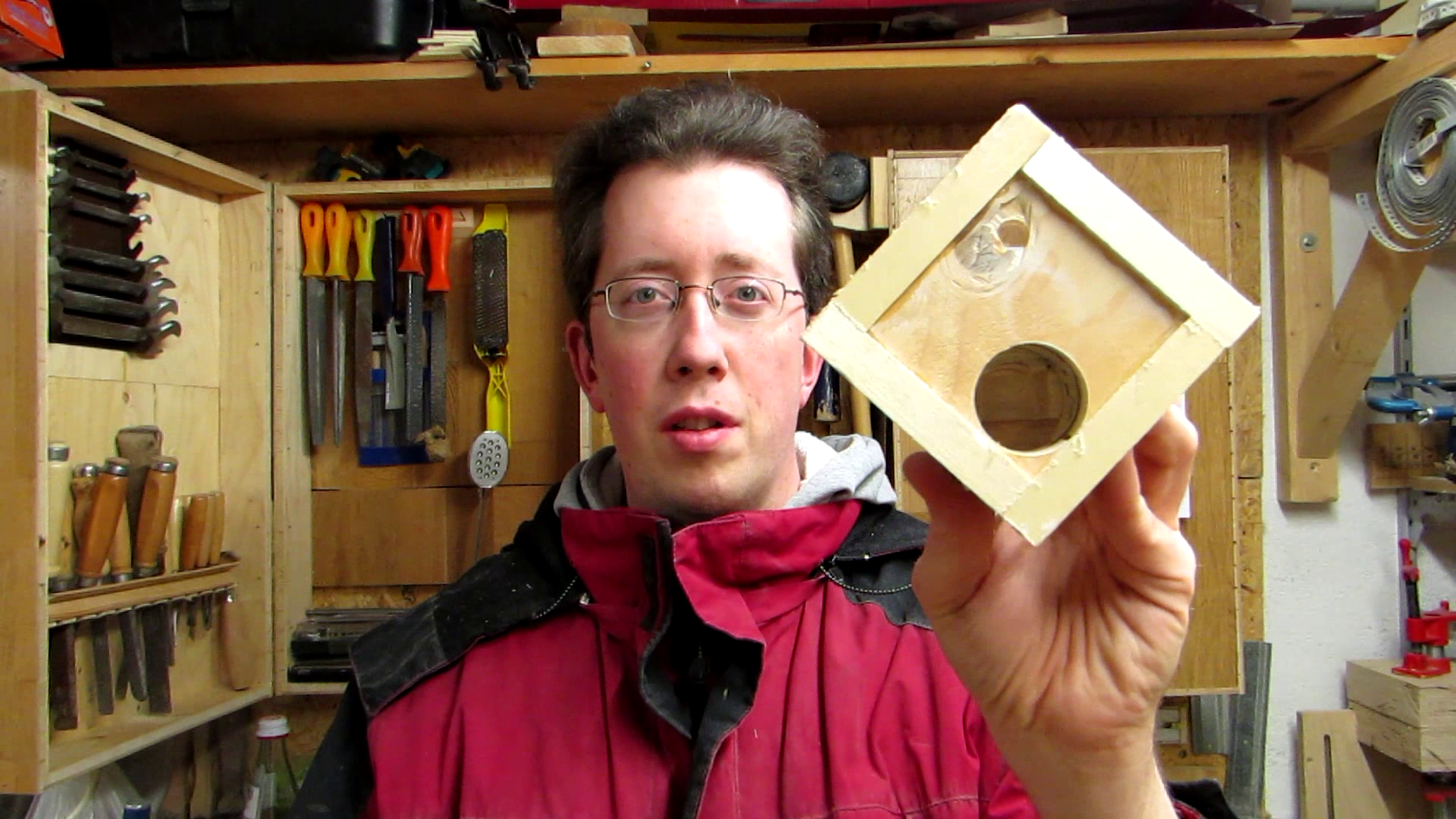

Today I share with you a technique to make multi-compartment trays or even shadow boxes from scrap pieces. With a slight modification, you can also make single storage boxes in large numbers for all your shop organization needs. And if you go that extra mile, you can turn what starts… Continue Reading Storage Boxes from scraps – Quick & Dirty